Lisebelisoa tsa boleng le Ts'ebetso ea Taolo ea Boleng

Li-valve kaofela li etsoa ke sistimi e ntle ea taolo ea boleng, lisebelisoa tse tšepahalang tsa tlhahlobo le basebetsi ba koetlisitsoeng ba QC, ARAN e boloka boleng e le ba bohlokoa ka ho fetisisa ho moreki oa rona.

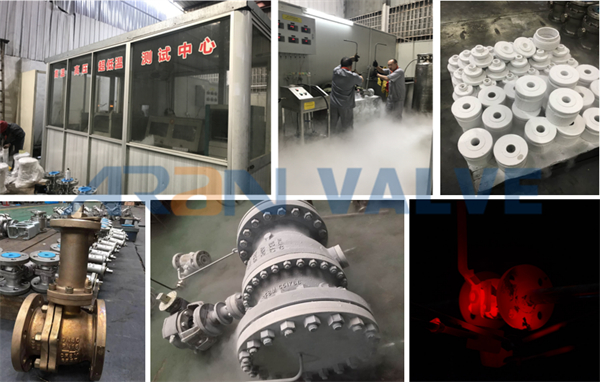

ARAN e na le lefapha la liteko tsa ka tlung hape le lab e lumelletsoeng ke motho oa boraro bakeng sa taolo e khethehileng ea boleng, litlhahlobo tsohle le liteko li etsoa ke batho ba tšoanelehang le ba nang le boiphihlelo.

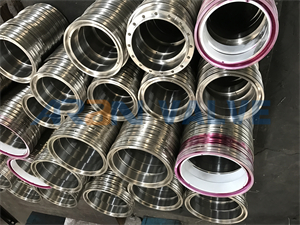

Setsi sa lisebelisoa tsa taolo ea boleng ba ntlo, e leng tlhahlobo ea phello, teko ea boima, tlhahlobo ea tensile, sebopeho sa lik'hemik'hale le lab ea thepa ea mochini jj.

Ka taelo eaMoralo oa Taolo ea Boleng (QCP) le Tlhahlobo leTlhahloboLeano la Teko (ITP) le ka fanoa bakeng sa tumello ea Moreki pele ho tlhahiso.

1. Taolo ea thepa e tala ea Valve: Tlhahlobo ea pono le boholo, PMI, Botenya ba Lerako, Teko ea Tšusumetso haeba ka kopo, NDE joaloka PT, UT, MT, RT.

2. Tlhahlobo ea mochine oa mochine oa valve: ho hlahloba boholo, ho hlahloba holim'a mochine le lisebelisoa tsa likarolo, kopo e khethehileng joaloka tlhahlobo ea NDE ka kopo ea taelo.

3. Tlhahlobo ea li-valve le tlhahlobo ea ts'ebetso: Karolo e 'ngoe le e' ngoe ea valve e tlas'a tlhahlobo ea hydraulic le moea tlhahlobo ea ts'ebetso ho latela kopo e tloaelehileng ea taelo, kopo e khethehileng joaloka tlhahlobo ea PAT ka kopo ea taelo.

4. Pente ea Valve, sephutheloana le ho pepa.Kopo e khethehileng joalo ka tlhahlobo ea motho oa boraro ka kopo ea taelo.

Kakaretso Quality Control Process

Taolo ea thepa e tala ea valve: Tlhahlobo ea pono le boholo, tlhahlobo ea thepa, PMI, Botenya ba lebota, Teko ea phello haeba ka kopo, NDE.

Tlhahlobo ea ts'ebetso ea mochini oa li-valve: cheke ea boholo, sefahleho se entsoeng ka mochini le lisebelisoa tsa likarolo, kopo e khethehileng joalo ka tlhahlobo ea NDE ka kopo ea odara.

Kopano ea li-valve le tlhahlobo ea ts'ebetso: Karolo e 'ngoe le e' ngoe ea valve e tlas'a tlhahlobo ea hydraulic le moea tlhahlobo ea ts'ebetso ho latela kopo e tloaelehileng ea taelo.

Pente ea Valve, sephutheloana le thomello.

Kopo e khethehileng ea Bolaoli ba Boleng

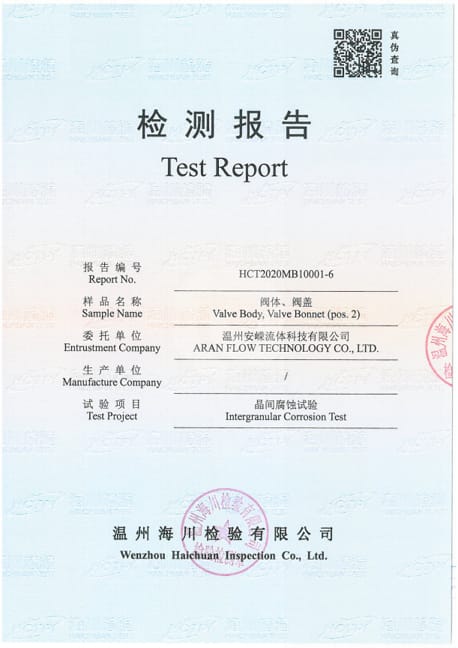

Tlaleho ea tlhahlobo ea lintho tse bonahalang lab ea batho ba bang

- Teko ea mochini le ts'usumetso

- Tlhahlobo ea tlhahlobo ea lik'hemik'hale

- Teko ea kutu

- Cheke ea ferrite

- Teko ea ho phatloha e kentsoeng ka hydrogen (HIC)

- Sulphide Stress corrosion cracking test

Teko e sa Senyeng (NDE, NDT)

Ts'ebetso ea VT, PMI, UT, PT e ka etsoa ka lapeng le motho oa boraro ea etsang UT, PT, MT, RT le boima, 'me e kenyellelitse boemo ba thuto ea lintho tseo bohle ba tla li etsa acc.ho litlhoko tsa taelo ea bareki.

- VT (Teko ea Pono)

- PMI (Positive Material Identification)

- UT (Teko ea Ultrasonic)

- PT (Teko ea Penetrant)

- MT (Teko ea Magnetic particle)

- RT (teko ea X-Ray)

- Teko ea boima

Teko ea Khatello & Mosebetsi

Litekanyetso tsa liteko joalo ka API 598,API 6D,ISO 5208,EN12266-1,GOST 9544 joalo-joalo.

- Teko e sebetsang / Teko ea boleng ba Torque

- Teko ea Hydraulic / Teko ea moea

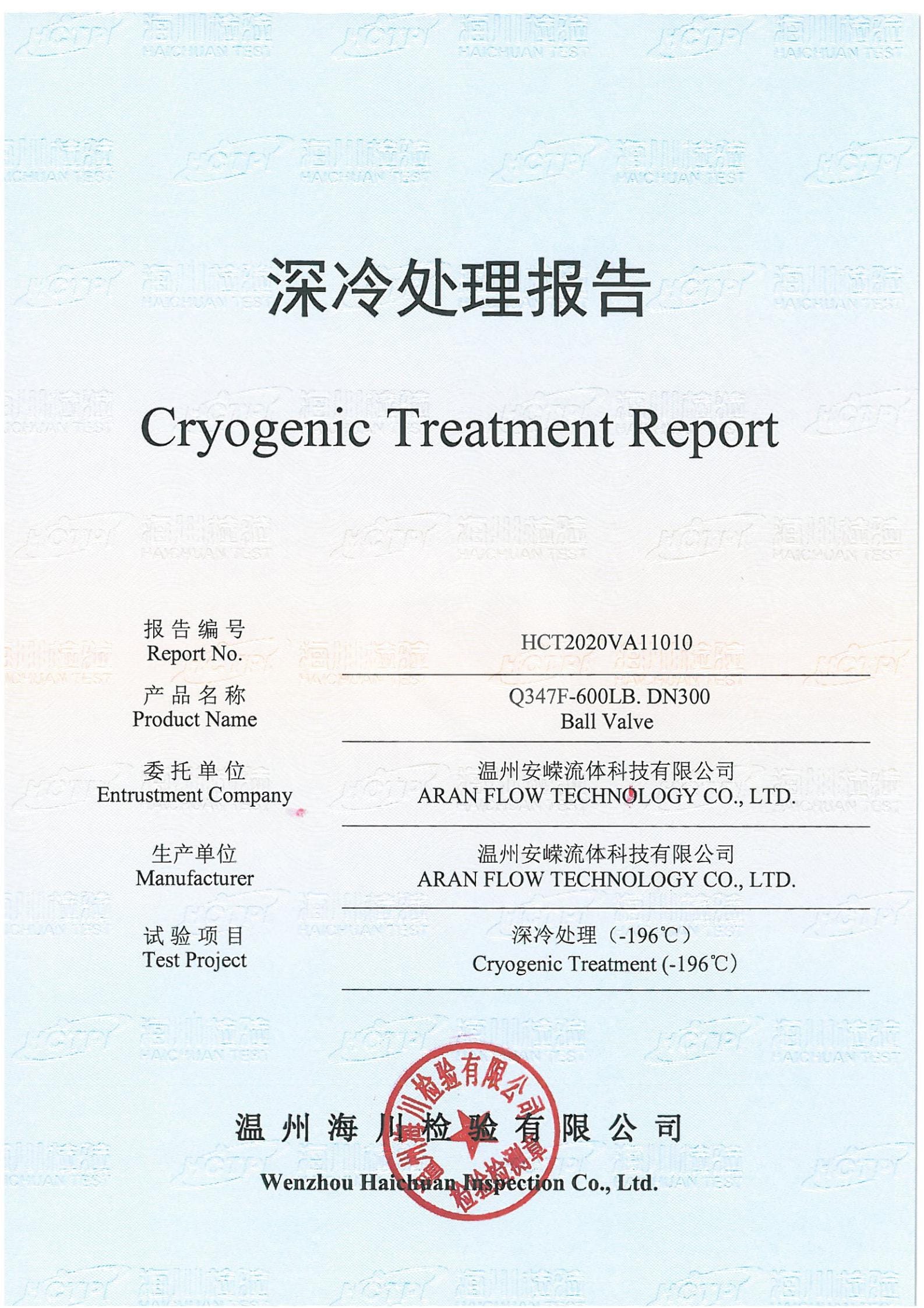

- Teko e tlase ea mocheso oa khase ea Cryogenic Helium -196°C

- Teko e phahameng ea mocheso 600°C

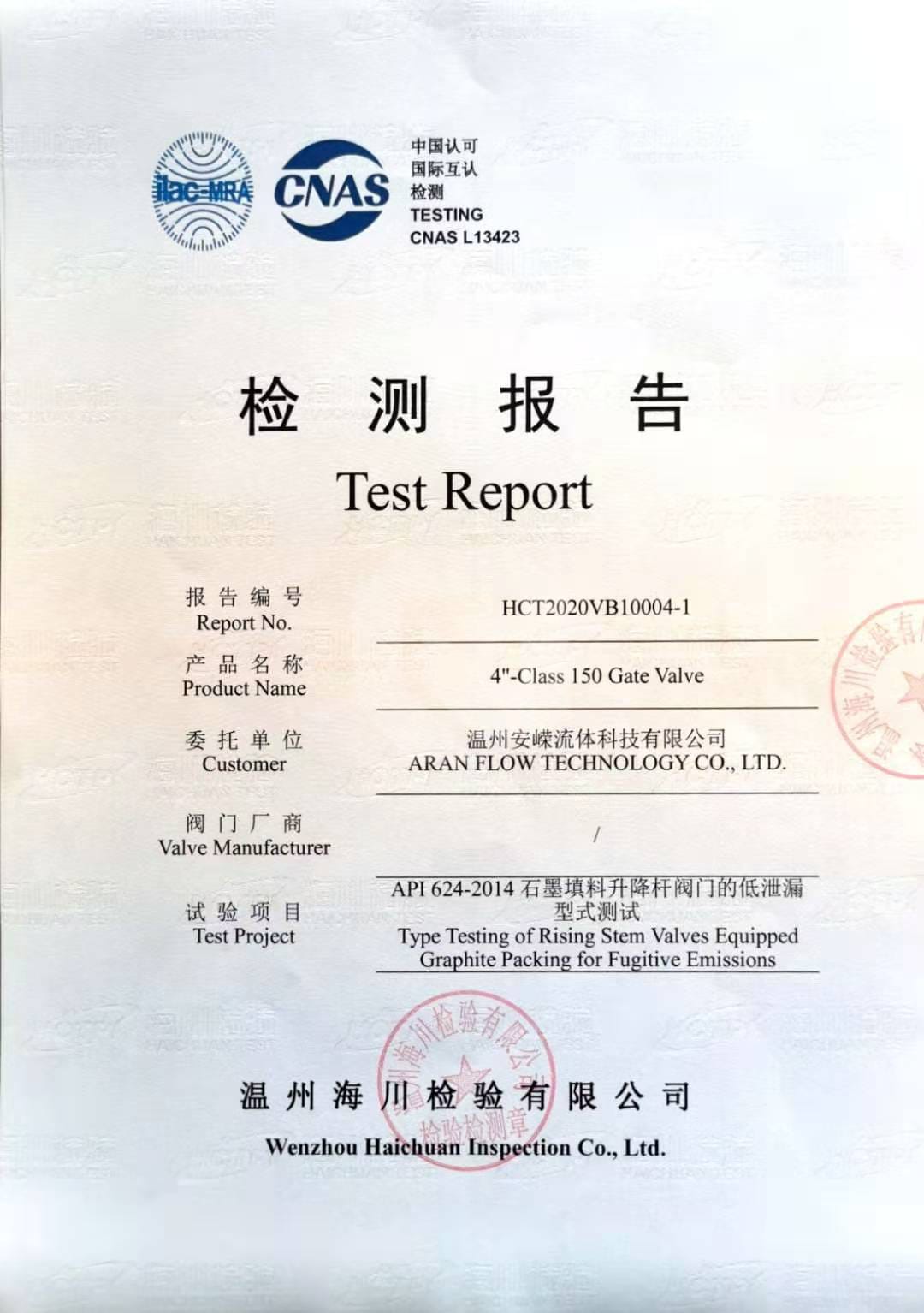

- Teko ea ho Fugitive Emission 15848-1 kapa 15848-2

- Teko e sireletsehileng ea mollo

- Teko ea FAT (teko ea kamohelo ea fektheri)

- Teko ea PAT (teko ea ho amohela sehlahisoa)

Teko ea mocheso o tlase: lisebelisoa tsa laborateng tsa mocheso o tlase le o phahameng ho etsa liteko tsa mocheso o tlase kapa o phahameng ho latela litlhoko tsa odara.Teko e pepesetsa valve tekong ea mocheso o tlase oa Cryogenic -196 ℃ kapa mocheso o phahameng -538 ℃